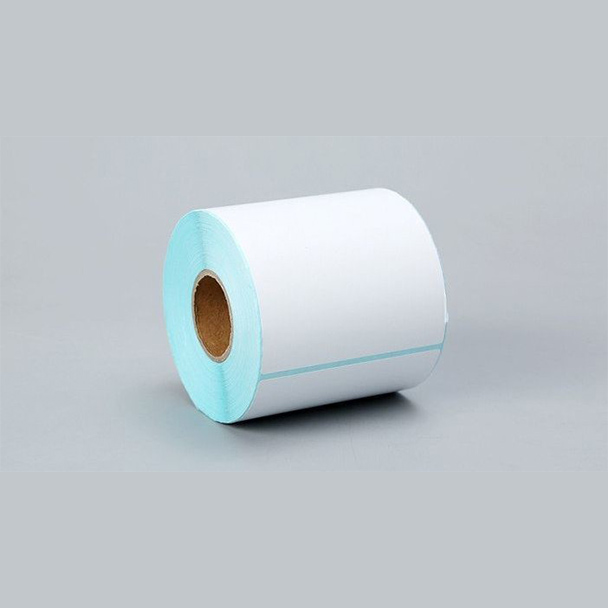

DIRECT THERMAL BARCODE LABEL

Direct Thermal Barcode Label have a heat sensitive coating on the face stock which enables these products to be imaged with a barcode printer and does not require a ribbon.

Non Top Coated Paper – Paper labels utilize a paper base stock to which a thermal coating has been applied

Top Coated Paper – Premium Paper labels are smooth, bright, white paper with a high sensitivity thermal coating.

Bright white labels provide excellent printability for low to medium-speed printers

Direct thermal printers typically cost less to operate than inkjet, laser or thermal transfer printers

While direct thermal labels offer many advantages, they’re not suited for labels that must remain legible for years or survive particularly harsh environments. Direct thermal materials are highly sensitive to light, heat and heavy contact, making them susceptible to fading in the long term

APPLICATION :-

- Direct thermal labels have long been used for meat, poultry and dairy products

- Direct Thermal shipping labels

- Amazon Direct Thermal Shipping Labels

- In Hospital patient and visitor identification

- Receipts and ticket printing

- Name tags and visitor passes, Coupons in Event Show

FEATURES :-

- Cost-effectively printing

- Direct thermal labels print on continuous reels or sheets and are highly cost effective for creating simple labels in large quantities

- Since they use no thermal ribbon, they’re a more environmentally friendly option

- Time savings during the printing process, since thermal printing eliminates the need to monitor and reload ribbons

- Elimination of wrinkling due to ribbons

- Reduction in physical inventory

TYPE :-

- Roll Form

CORE :-

- 1” Core , 2” Core & 3” Core

PACKING :-

- Rolls are packed Stretch Film. Rolls are wrapped in Polythene Covers and packed in bundles.

PRINTABILITY :-

- Printable with Wax Ribbon

COLOR :-

- White