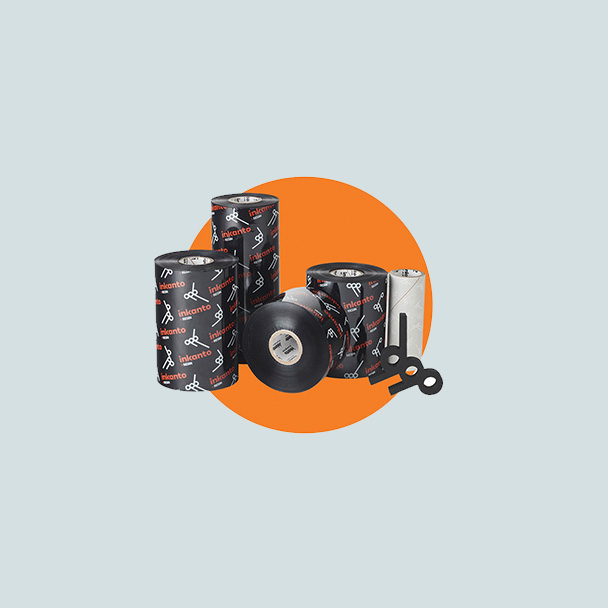

RESIN RIBBON

Resin Thermal Transfer ribbons are designed for the most demanding APPLICATION :- in need of resistances to mechanical stresses, high or low temperature environments, or even solvents.

Resin Ribbons Will Deliver A Great Print Quality On The Following Label Materials

- Paper labels: Glossy coated

- Synthetic labels: Polypropylene, Polyethylene, Polyester

- Specific labels: Polyimide, Acrylate, textile

- Flexible packaging films

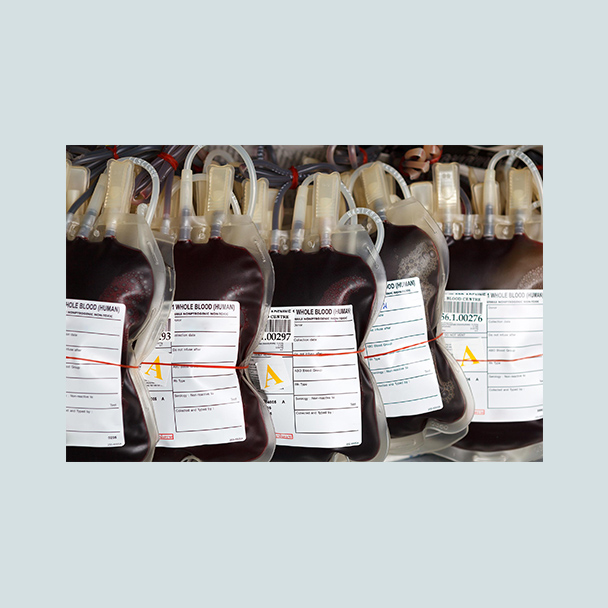

APPLICATION :-

- Laboratories

- Signage and logos

- Rating plate

- Medical device

- Industrial labels

- Electrical component

- Bag of parts/products

- Blood bag

- Plant marking

- Chemicals

- Printed circuit board

- Care labels

- Tyres

- Frozen food packaging

- Hot food packaging

- Flexible packaging

ADVANTAGES :-

- High print durability even in very harsh environment

- Print durability: good resistance to scratch, smear, scuffing or rubbing.

- Excellent resistance to solvents and to high temperature

- Excellent resistance to smudge and scratch

- Good resistance to high temperature

- Excellent printing quality thanks to a high sharpness capability

What Makes A Resin Ribbon Different From Wax And Wax-Resin And Resin Ribbon?

- Print resistance: Resin ribbons provide the highest durability compared to any other Thermal Transfer ribbon

- Print speed: Resin inks require more energy from the printhead to transfer on the receptor. Therefore, the printer speed must be lower (max 10ips) compared to Wax-resin ribbons.

- Label compatibility: Resin ribbons deliver a premium print quality on premium label materials and also on specific materials like textile garment labels for example. However, the versatility of a Resin ribbon is more limited compared to a Wax-resin ribbon especially on uncoated or some coated papers.

- Printer compatibility: Similar to Wax-resin ribbons, there are Resin ribbons to run with all Thermal printers or coders regardless the printhead technology. This is why there are Resin ribbons for Flat-head printers and Resin ribbons for Near-edge/Corner-edge printers.

FEATURES :-

- Ability to print on a variety of media: papers, synthetics and textile labels, packaging films

- Consumables are easy to use and replace

- Print labels speed compatible with high throughput of many production and packaging lines

- Cleanliness of the process

- Operator safety

- Robustness of printers well suited to the manufacturing environment

- Low maintenance

- Competitive print cost

SIZE :-

- All size Available as per the requirements

CORE :-

- ½ “ , 1” , Etc.