WAX RIBBON

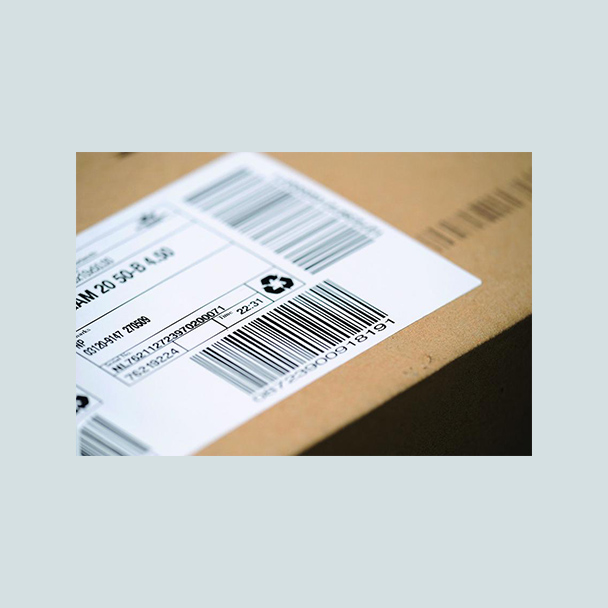

A wax ribbon is a ribbon coated with an ink made essentially with wax-based components. Wax ribbons are the most popular thermal transfer ribbon for thermal printers. Wax-based inks have a good adhesion on almost all types of substrate and are perfectly suitable for printing barcodes and other types of labels.

Wax Ribbons Will Deliver A Great Print Quality On The Following Label Materials

- Rough vellum papers

- Matt coated papers

- Glossy coated papers

APPLICATION :-

- Storage

- Shipping

- Crate

- Distribution labels

- Tags

- Bag of parts/products

- Signage and logos

ADVANTAGES :-

- Ideal for short-term use

- Good printing quality: ensures a good readability/scanning of barcodes, digits and characters

- Fast print speed up to 12 ips depending on the label/ribbon combination

- Good ink blackness, even on rough label materials like velum

- Competitive ribbons: lower prices than wax-resin and resin based ribbons

- Receptor multi-compatibility: the ink has a good adhesion on coated or uncoated labels

- Low energy required to transfer the ink: helping to extend the print head lifetime

What Makes A Wax Ribbon Different From Wax-Resin And Resin Ribbon?

- Print durability: It’s a softer ink more vulnerable to scratching and smudging. For APPLICATION :- requiring a more durable ink, it will be appropriate to use wax-resin or resin ribbons

- Printer compatibility: wax ribbons are working on Flat-head printers, whereas Wax-resin and Resin ribbons can also run on Near-Edge printers.

- Printhead heat setting: Wax inks have a lower melting temperature compared to Wax-resin and Resin ribbons. Therefore, they impose less stress to the print head

- Label compatibility: Wax ribbons are suitable for uncoated or matt coated surfaces. For synthetics labels, Wax-resin and Resin ribbons are more adapted

FEATURES :-

- Robustness of printers well suited to the manufacturing environment

- Low maintenance

- Ability to print on a variety of media: papers, synthetics and textile labels, packaging films

- Consumables are easy to use and replace

- Print labels speed compatible with high throughput of many production and packaging lines

- Competitive print cost

- Cleanliness of the process

- Operator safety

SIZE :-

- All size Available as per the requirements

CORE :-

- ½ “ , 1” , Etc.